Enzyme Activity Calculator

Enzyme Activity Formula

Enzyme activity is generally measured by the rate at which an enzyme converts substrate into product. The commonly used formula is:

Enzyme Activity (U/mL) = (ΔA × V<sub>total</sub>) ÷ (ε × d × V<sub>enzyme</sub> × t)

Where:

- ΔA = Change in absorbance per minute

- Vₜₒₜₐₗ = Total reaction volume (in mL)

- ε = Molar extinction coefficient (M⁻¹ cm⁻¹)

- d = Path length of cuvette (in cm)

- Vₑₙ𝓏ᵧₘₑ = Volume of enzyme used (in mL)

- t = Time in minutes

Table of Contents

What is Enzyme Activity in Textile Processing?

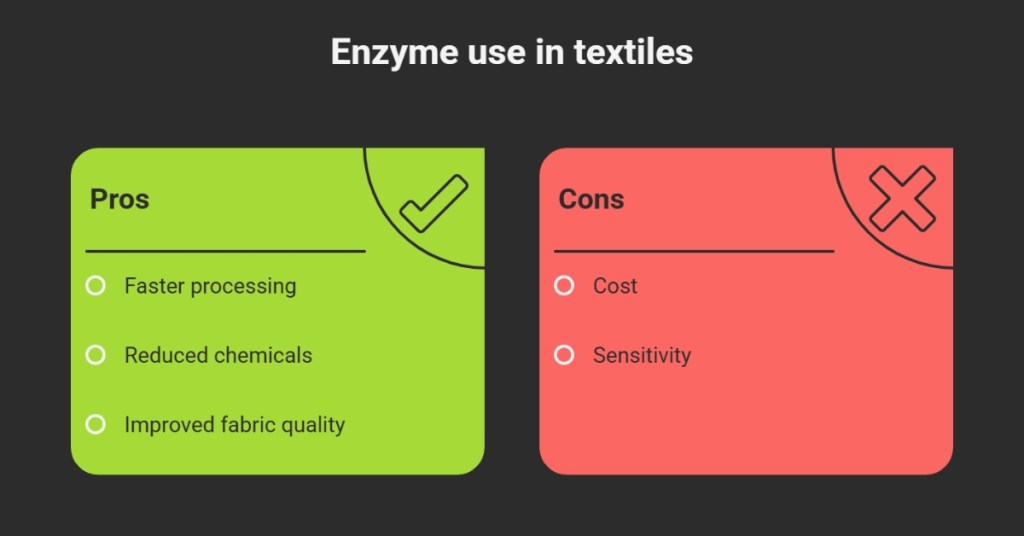

Enzyme activity shows how fast an enzyme works in a chemical reaction. In textile processing, enzymes help remove starch, soften fabrics, and improve dye uptake. Enzymes speed up these steps and reduce the use of harsh chemicals.

The efficiency of the enzyme depends on how active it is. Higher activity means better and faster results in the fabric treatment process. We use simple formulas to calculate this activity.

Why Enzyme Activity Matters in Textile Engineering

Controls the Quality of Fabric Treatment

As a textile engineer, I use enzymes in many wet processing stages. Enzyme activity shows how effective the enzyme is. If the activity is too low, the fabric will not process properly. For example, in bio-polishing or desizing, enzyme activity helps remove fuzz or starch from cotton fabrics. Proper activity ensures a smooth fabric with less damage.

Reduces Waste and Saves Time

High enzyme activity means faster reaction times. It reduces the need for extra chemicals, high temperatures, or long processing hours. This helps save water, steam, and energy, which lowers production costs.

How to Use the Enzyme Activity Calculator

Step-by-Step Calculation

To use the calculator, follow these steps:

- Enter the change in absorbance (ΔA) per minute.

- Input the total volume of the reaction.

- Add the extinction coefficient of the substrate.

- Set the cuvette path length (usually 1 cm).

- Enter the enzyme solution volume used.

- Input the reaction time in minutes.

- Click “Calculate” to see the activity result in U/mL.

The result tells you how active the enzyme is under those test conditions. This value helps decide how much enzyme to use in a batch.

Example in Textile Processing

Let’s say I run a desizing process in my lab. I use the α-amylase enzyme. The absorbance change is 0.3 per minute. The total volume is 3 mL. The extinction coefficient is 6220 M⁻¹ cm⁻¹. The cuvette path length is 1 cm. I use 0.1 mL of enzyme solution, and the test time is 5 minutes.

Using the formula:

Enzyme Activity = (0.3 × 3) ÷ (6220 × 1 × 0.1 × 5)

This result tells me the enzyme is working at a low rate. So, I might need to increase the enzyme dose or change the temperature to improve activity.

Key Benefits of Using This Calculator

Easy to Use

The calculator uses a simple form and default values. Even beginners can check enzyme performance by just entering a few values.

Accurate and Fast

It uses a reliable formula used in textile labs. The output shows clear results in seconds. You don’t need to do manual math or use Excel formulas.

Helps in the Lab and Factory

Whether you are working in a textile lab or running a production batch, this calculator is useful. You can test enzyme samples and make decisions based on real data.

Enzyme Activity in Sustainable Textile Production

Today, sustainability matters in the textile industry. Enzymes replace harsh chemicals in many wet processes. For example, we use cellulase enzymes in bio-polishing to reduce pilling. We use pectinase for scouring. These enzymes work best when their activity is high.

By using this calculator, textile factories can monitor enzyme batches, avoid overuse, and reduce waste. This practice supports green production goals.

Final Thoughts

I use this tool regularly in R&D and production setups. It helps check enzyme efficiency without lab complexity. The Enzyme Activity Calculator is a useful companion in quality control and lab testing.

Whether you are a student, lab technician, or textile professional, this tool saves time and improves decision-making. It supports better process control and helps meet eco-friendly production targets.