Average Garments Thread Consumption

© Textile Calculator Ltd. All rights reserved.

Disclaimer: All calculators in the Textile Calculator have been reviewed by the relevant textile industry experts.

Garment thread consumption plays an important role in textile manufacturing. Estimating thread consumption accurately helps save cost and maintain garment quality. Many factors affect thread usage in garments. These include seam type, stitch type, fabric thickness, and sewing machine operations. As a textile engineer and fashion designer, I will explain the step-by-step process for calculating thread consumption.

Table of Contents

What Is Garments Thread Consumption?

Thread consumption refers to the length of thread used to stitch a garment. Manufacturers measure thread usage in meters per garment. The calculation includes thread wastage during sewing. Factories use thread consumption data to estimate material requirements and production costs.

How to Calculate Thread Consumption

Factories use three methods to determine thread usage:

1. Mathematical Formula:

Thread consumption = (Seam length × Stitch density) × Wastage factor

Example:

- Seam length: 1.5 meters

- Stitches per cm: 5

- Wastage: 5%

Calculation: (1.5 × 5 × 100) × 1.05 = 787.5 cm (7.875 meters)

2. Thread Measurement Machine

Specialized machines measure thread pulled during stitching.

3. Industry Reference Tables

Predefined values for common garments simplify estimation.

Why Thread Consumption Matters

- Cost Control – Thread accounts for 1-3% of total garment cost. Accurate calculations prevent overordering.

- Quality Assurance – Proper thread tension and length ensure durable seams.

- Production Planning – Factories forecast thread needs for bulk orders efficiently.

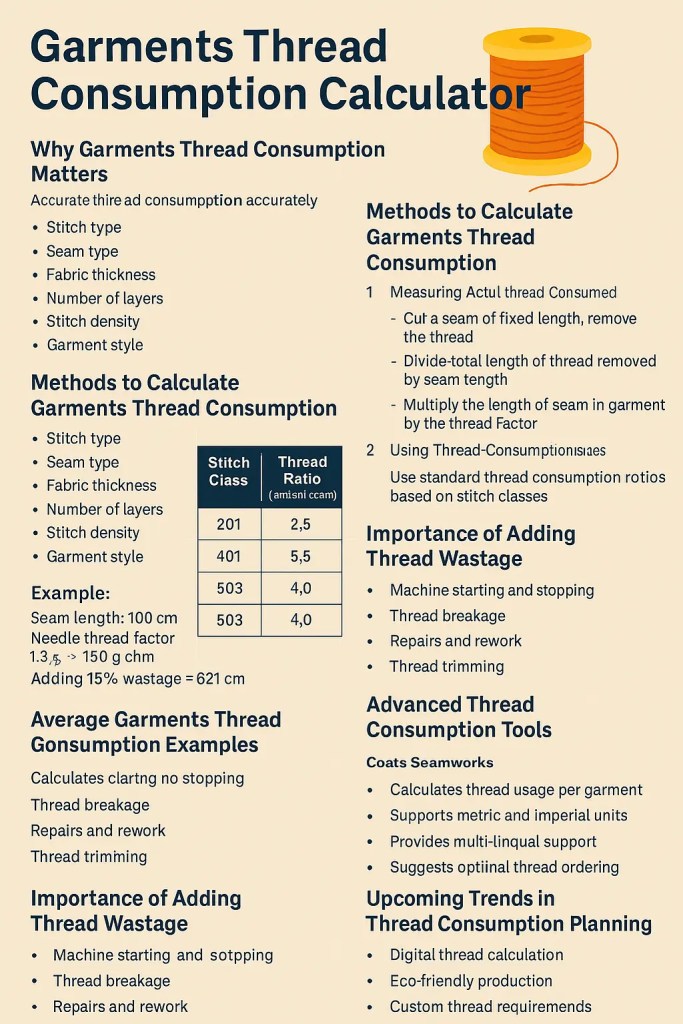

Why Garments Thread Consumption Matters

Accurate thread consumption helps control production costs. It ensures the right quantity of thread is ordered. It avoids thread shortages or excess inventory. Proper thread planning improves sewing efficiency. It also maintains garment strength and appearance. In today’s competitive market, accurate thread calculation gives manufacturers a clear advantage.

Factors Affecting Garments Thread Consumption

Many factors influence thread consumption in garments. These include:

- Stitch Type: Different stitches like lockstitch, chainstitch, or overlock use different amounts of thread.

- Seam Type: Seam construction and design change the thread length.

- Fabric Thickness: Thicker fabrics require more thread.

- Number of Layers: More fabric layers increase thread usage.

- Stitch Density: Higher stitches per inch (SPI) consume more thread.

- Garment Style: Variations in styles like shirts, jeans, or jackets affect thread requirements.

Each of these elements needs to be considered carefully during production planning.

Methods to Calculate Garments Thread Consumption

There are two common methods to calculate garments thread consumption:

1. Measuring Actual Thread Consumed

- Cut a seam of a fixed length.

- Remove the thread carefully from the seam.

- Measure the total length of the thread pulled out.

- Divide the total thread length by the seam length.

- Multiply the thread factor by the total seam length in the garment.

Example:

Seam length = 100 cm

Needle thread factor = 1.3

Looper thread factor = 4.1

Total thread consumed = (100 × 1.3) + (100 × 4.1) = 540 cm

Adding 15% wastage: 540 × 1.15 = 621 cm

This method provides the most accurate results for new designs.

2. Using Thread Consumption Ratios

Another method is using standard thread consumption ratios. These ratios depend on stitch type and seam length. You can use tables based on stitch classes.

Example of Thread Ratios:

| Stitch Type | Stitch Class | Thread Ratio (cm/cm seam) |

|---|---|---|

| Lockstitch | 301 | 2.5 |

| Chainstitch | 401 | 5.5 |

| Overedge | 503 | 4.0 |

Example:

For a chainstitch (Class 401) seam of 100 cm:

Total thread = 100 × 5.5 = 550 cm

Adding 15% wastage: 550 × 1.15 = 633 cm

This method saves time and provides good estimates for large production runs.

Average Garments Thread Consumption Examples

From industrial experience, the average thread consumption for common garments is:

| Garment Type | Average Consumption (meters) |

|---|---|

| Men’s Shirt | 120 |

| Men’s Jeans | 200 |

| Basic T-shirt | 55 |

| Dress | 195 |

| Jackets | 210 |

These figures include about 5%-15% thread wastage.

Importance of Adding Thread Wastage

In real production, some thread gets wasted. Reasons include:

- Machine starting and stopping

- Thread breakage

- Repairs and rework

- Thread trimming

Manufacturers usually add 10%-15% extra thread to the calculated consumption. This ensures smooth operations without a shortage during production.

Advanced Thread Consumption Tools

Today, many textile factories use software tools like Coats Seamworks. This sewing management system helps calculate thread consumption digitally. It reduces human errors. It also helps in cost control and thread inventory planning. Using such tools improves production speed and accuracy.

Key Features of Seamworks:

- Calculates thread usage per garment

- Supports metric and imperial units

- Provides multi-lingual support

- Suggests optimal thread ordering

Many garment manufacturers are now shifting to digital solutions to remain competitive.

Optimizing Thread Usage in Production

1. Reduce Wastage

- Train operators to minimize thread breaks.

- Maintain sewing machines to prevent tension issues.

2. Choose Efficient Stitches

- Use lockstitch (301) instead of chain stitch (401) where possible.

- Opt for 3-thread overlock instead of 5-thread safety stitches.

3. Monitor Consumption Regularly

- Compare actual usage with standard values.

- Adjust calculations for fabric variations.

Upcoming Trends in Thread Consumption Planning

Modern textile industries are moving towards:

- Digital thread calculation: More factories are using software tools.

- Eco-friendly production: Reducing thread wastage to lower environmental impact.

- Automation: Sewing machines with thread monitoring sensors are becoming common.

- Custom thread requirements: Fashion brands demand special thread finishes, like anti-bacterial or fire-resistant threads.

These trends are shaping a smarter, faster, and greener textile industry.

Conclusion

Garment thread consumption plays a critical role in textile production. Proper calculation saves cost, reduces waste, and improves garment quality. Manufacturers must choose the correct method depending on their needs. By measuring actual thread or using thread consumption ratios, garment producers can plan efficiently. Modern solutions like Seamworks provide further advantages. As a textile engineer and fashion designer, I recommend combining traditional methods with modern technology for best results.