GSM Calculator by Warp, Weft and Count

Formula for GSM Calculator by Warp, Weft and Count

The formula to calculate GSM (Grams per Square Meter) is:

Let’s break down the terms in the formula:

- Warp: The number of vertical threads in the fabric. These threads are stretched on the loom.

- Weft: The number of horizontal threads in the fabric. These threads are woven across the warp.

- Warp Count: The thickness or weight of the warp yarn, often given in tex or denier.

- Weft Count: The thickness or weight of the weft yarn, also given in tex or denier.

The formula uses a constant of 47, which is specific to the calculation based on fabric type and machine setup. The value of 5 added at the end is a small correction factor to refine the result.

Table of Contents

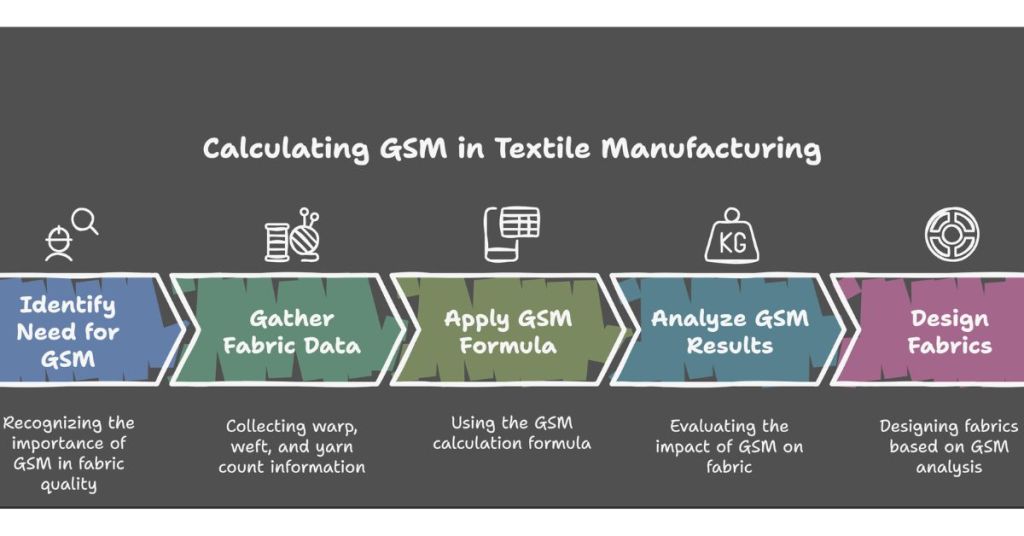

The GSM (grams per square meter) of fabric is an essential parameter in textile manufacturing. It determines the density and weight of the fabric, affecting its quality and performance. Textile engineers rely on GSM calculations for designing fabrics that meet specific standards. The GSM can be calculated using a simple formula involving warp, weft, and yarn counts. In this article, we will discuss how to calculate GSM using warp, weft, and yarn counts. We will explain the process step by step and describe its importance in textile manufacturing.

Step-by-Step Process for GSM Calculation

To calculate GSM, follow these steps:

- Determine the Warp and Weft: The warp and weft counts are usually measured per inch or per centimeter of fabric. These counts depend on the fabric type and manufacturing process. Measure the number of warp and weft threads in a given length of fabric.

- Measure the Warp Count and Weft Count: Warp and weft counts are crucial to understanding fabric density. Measure the thickness of the warp and weft yarns, which is typically expressed in tex or denier. Tex refers to the weight of the yarn in grams per 1000 meters, while denier is a similar unit but is based on the weight per 9000 meters.

- Apply the Formula: Plug the values for warp, weft, warp count, and weft count into the formula. Multiply the sum of the warp and weft by 47, and then divide that by the sum of the warp count and weft count. Finally, add 5 to the result.

- Interpret the Result: The result from the formula will give you the GSM value of the fabric. This value helps determine the fabric’s weight and is essential for quality control, fabric selection, and cost estimation in textile manufacturing.

Example Calculation of GSM:

Let’s calculate the GSM (Grams per Square Meter) for a fabric with the following specifications:

- Warp threads: 120

- Weft threads: 60

- Yarn count: 40

To find the GSM, use the formula:

GSM = (Warp threads + Weft threads) × 47 / (Yarn count + Yarn count) + 5

Now, substitute the given values into the formula:

GSM = (120 + 60) × 47 / (40 + 40) + 5

This simplifies to:

GSM = 180 × 47 / 80 + 5

After calculating:

GSM = 110

Thus, the fabric has a GSM of 110.

Importance of GSM in Textile Manufacturing

GSM is a critical measure in textile manufacturing. It directly affects fabric weight, strength, and durability. Fabrics with higher GSM are heavier and more durable, making them suitable for items like jackets and upholstery. Fabrics with lower GSM are lighter and often used for items like shirts and bedding.

By calculating GSM, textile engineers can ensure that the fabric meets specific standards for weight and durability. This helps in selecting the right material for different types of garments or textile products. Accurate GSM measurement also contributes to maintaining quality control during production.

Factors Affecting GSM Calculation

Several factors can influence the GSM calculation in textile manufacturing:

- Thread Thickness: The thickness of the warp and weft yarns can affect the fabric’s GSM. Finer threads result in a lighter fabric, while thicker threads lead to a heavier fabric.

- Weaving Density: The number of warp and weft threads per unit length influences GSM. A higher density of threads results in a higher GSM.

- Fabric Type: Different types of fabrics, such as woven, knitted, or nonwoven, may have varying GSM values. The GSM of each fabric type depends on its structure and intended use.

- Finishing Treatments: Some finishing treatments like dyeing, printing, or coating can add weight to the fabric, which may affect the final GSM.

Understanding these factors helps textile engineers make adjustments to the production process to achieve the desired GSM for a particular fabric.

Applications of GSM in the Textile Industry

The GSM value is used in various applications within the textile industry:

- Fabric Quality Control: GSM helps ensure that fabric meets the required weight specifications. This is important for maintaining uniformity in production.

- Cost Estimation: Since fabric weight impacts the material cost, calculating GSM allows manufacturers to estimate the cost of raw materials accurately.

- Product Design: GSM is a key consideration in product design. For example, the GSM of a fabric determines its suitability for clothing items like shirts, trousers, or outerwear.

- Garment Manufacturing: The GSM value helps manufacturers select the right fabric for specific garments. It ensures that the fabric will perform as expected, providing the necessary strength, comfort, and appearance.

Conclusion

The GSM calculator by warp, weft, and count is an essential tool in textile engineering. It helps calculate the weight and density of fabric, which directly affects its quality and usability. By understanding the formula and following the correct procedure, textile engineers can ensure that the fabric meets the required specifications for various applications. The GSM value is crucial for quality control, cost estimation, and product design in textile manufacturing. Understanding how to calculate and interpret GSM is an important skill for anyone working in the textile industry, as it ensures that the fabric performs as intended and meets the necessary standards.