Gauge to kg Calculator

© 2010 – Textile Calculator Ltd.

Disclaimer: All calculators in the Textile Calculator have been reviewed by the relevant textile industry experts.

Formula for “Gauge to kg”

To estimate fabric weight in kilograms from gauge, a simple formula is used:

Estimated Weight (kg) = (Gauge × Width × Length × Fabric Constant) / 100000

Where:

- Gauge = Number of needles per inch

- Width = Tube diameter (in inches) × π (approximated as 3.14)

- Length = Fabric length in meters

- Fabric Constant = A machine/yarn dependent value (default ≈ 0.025 for general jersey)

This is a general estimation formula. Actual weight may vary based on GSM, machine settings, etc.

Table of Contents

What is Gauge in Knitting?

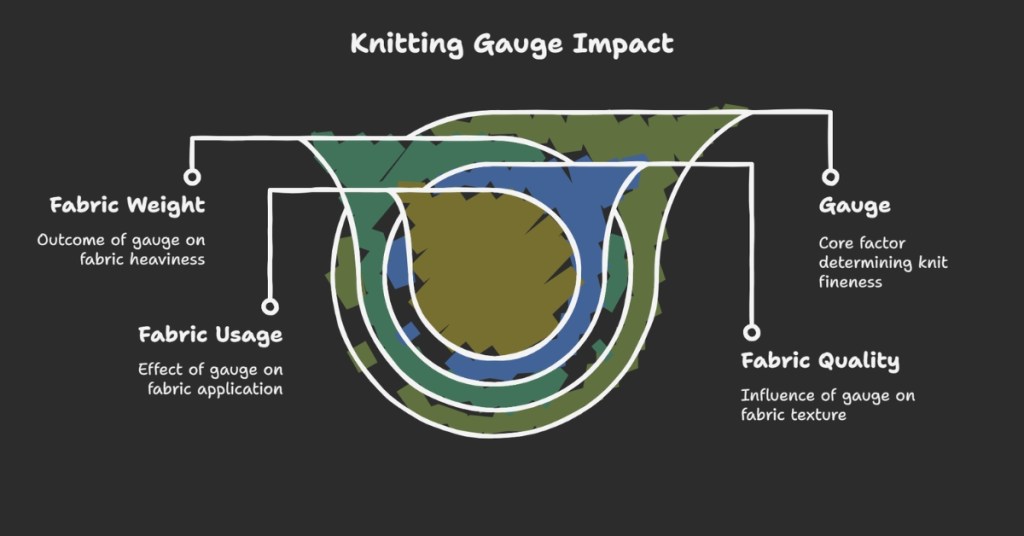

Gauge is the number of needles per inch in a knitting machine. It shows how fine or coarse the machine is. A higher gauge means finer needles and a tighter knit. A lower gauge means thicker needles and a looser knit. Gauge is important because it affects fabric weight, quality, and usage.

Why Convert Gauge to Kilogram?

Textile engineers convert gauge to kilograms to estimate fabric weight. This helps control production, plan yarn usage, and set pricing. If you know the gauge, diameter, and length of fabric, you can quickly calculate the estimated weight in kilograms. This saves time and reduces fabric waste in bulk production.

Gauge to kg Conversion Example

Let’s take a simple example to apply the formula.

Input:

- Gauge = 28

- Tube Diameter = 30 inches

- Fabric Length = 100 meters

- Fabric Constant = 0.025

Step-by-Step:

- First, calculate width: Width = 30 × 3.14 = 94.2 inches

- Then use the formula: Weight = (28 × 94.2 × 100 × 0.025) / 100000

- Final result: Weight ≈ 0.66 kg

So, a 100-meter roll of fabric on a 28-gauge, 30-inch diameter machine will weigh around 0.66 kilograms using this method.

Importance in Textile Manufacturing

Gauge to kg conversion helps mill engineers during fabric planning. Knowing the estimated weight helps in:

- Reducing yarn waste

- Planning a production schedule

- Managing order quantity

- Improving cost control

- Estimating fabric output per shift

This is useful in large-scale knitwear factories, where fabric rolls are measured and cut in bulk.

Benefits of Using a Gauge to kg Calculator

A gauge-to-kg calculator makes life easier for production managers and textile engineers. It removes the need for manual math and reduces the risk of error. Engineers can enter gauge, diameter, and length to get an instant result.

This helps in:

- Quoting fabric weights in customer orders

- Estimating yarn usage

- Machine productivity tracking

- Time-saving in quality control

Best Practices in Gauge-based Weight Estimation

To get better results using the gauge to kg formula, follow these tips:

- Always use accurate gauge settings

- Measure diameter using fabric width, not cylinder size

- Use the right fabric constant (change if using rib, interlock, or fleece)

- Verify sample rolls before applying to large lots

Common Fabric Constants by Type

Different fabrics need different constants. Below are common values used in mills:

| Fabric Type | Fabric Constant |

|---|---|

| Single Jersey | 0.025 |

| Rib | 0.030 |

| Interlock | 0.035 |

| Fleece | 0.040 |

Always check with the sample fabric to set a proper value for your machine and yarn.

Conclusion

Gauge to kg conversion is a fast and practical method in textile production. It gives engineers control over weight estimates, which leads to better planning and lower waste. By using a simple formula or a digital calculator, you can save time and boost efficiency. This method is easy to apply in daily factory work and suits knitwear production lines.